Maximising Production Reliability & Efficiency With IIoT Compressed Air System Optimisation

- Ecoplant is a remote, cloud-based IIoT compressed air management solution!

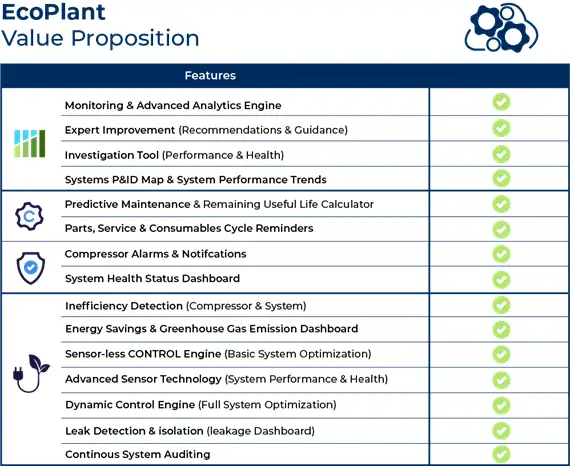

- What are the benefits of Ecoplant?

- Why choose Ecoplant for maximised savings opportunities?

Ecoplant is a remote, cloud-based IIoT compressed air management solution. By combining SAAS proactive analytics and controls with intuitive predictive maintenance, Ecoplant can automatically analyse and respond to your exact production needs. Its development using IIoT cloud-based technology, enables it to optimise your system using dynamic AI, stabilise pressure levels, minimise production outages, maintain ISO quality standards and detect and isolate leaks. This intuition means that most, if not all, outages are prevented before they happen, mitigating the risk of unexpected, costly downtime.

What Are The Benefits Of Ecoplant?

- Customised Dashboard & Reporting With Real-Time Data & Up-To-The-Minute Data

- Predictive Maintenance

- Cloud-Based & Remote Enabling On-Site Productivity & Off-Site Visibility

- State-Of-The-Art Dynamic Controls

- Total Cost Of Ownership Savings With Proactive Monitoring

- Reduce Energy Costs Through Optimised Efficiency

- Easily Detect and Isolate Leaks

- Reduce Carbon Footprint

- Trustworthy Pricing and Support

How Can Ingersoll Rand’s CARE™ Programs Help Maximise Your Savings Opportunities?

- Genuine Ingersoll Rand OEM parts are optimised for thermal conductivity and pressure drop, ensuring your compressed air system operates to specification, thus lowering your costs. The alternate use of non-OEM parts can have costly impacts on your operations, as they won’t align with compressor specifications, which can lead to potentially dangerous equipment issues. They also won’t be optimised for thermal conductivity, pressure drop or Ingersoll Rand’s standards. This can result in decreased performance and excessive operational costs.

- OEM parts are also delivered at preferred pricing to ensure your compressed air system operates to its exact specifications.

- PackageCARE™ offers more flexibility than an extended warranty, enabling you to add older equipment, filters, and dryers, or include a rental compressor without it increasing your costs. It also covers corrosion, wear and tear, materials, and workmanship.

- The inclusion of Helix™ ensures preventative 24/7 remote monitoring that alerts you of issues or inefficiencies before they become costly issues. This way, you can deal with issues before they become downtime, thus maximising your uptime!

Why Choose Ecoplant For Maximised Savings Opportunities?

An innovative feature of Ecoplant is its ability to produce predictive algorithms that assess daily, weekly, and seasonal energy use. From here, it can dynamically control your compressed air system via production profiles to effectively lower redundancy, energy waste, and excess utility costs.

Another cost-saving feature of Ecoplant is its state-of-the-art dynamic controls. But what does this mean? Well, typically operations use static control, which is a set-and-forget control strategy that is usually centralised from one control point only. This means that time-based event handling is locked down, preventing the adaptation to changing shifts. On the other hand, Ecoplant’s dynamic, AI-based control can optimise the production efficiency and reliability of your compressed air system by…

- Incorporating calculated air compressor flow and flow volatility into the decision-making process

- Constantly evaluating your system and evolving control strategies to meet dynamic plant environments

- Evaluating system pressure from the air compressor supply and adjusting settings in response to real-time demand changes Overall, this approach to compressor control and monitoring helps prevent downtime and reduce energy costs through optimised efficiency. With Ecoplant, you can enjoy optimised reliability, unmatched cost savings, and tomorrow’s tech at your fingertips!